Prevent Mechanical Warping of a PCB Connector during the Solder Reflow Cycle

Discover SV Microwave’s Reflow Stable RF PCB Connectors and their crucial role in preventing mechanical warping during the solder reflow cycle. Read on to learn more about these connectors' manufacturing processes, components, and applications.

Why Choose Reflow Stable Connectors?

The primary advantage of glass-sealed insulated connectors over traditional PTFE insulated connectors is their ability to maintain mechanical integrity and durability during the solder reflow cycle. During this process, PTFE connectors often suffer damage and distortion, while glass-sealed connectors offer superior stability. For engineering companies working on large PCB designs, frequently replacing damaged connectors can be a hassle. Glass-sealed connectors are designed to maintain integrity throughout the reflow cycle, offering multiple benefits:

- Capability of multiple solder reflow cycles

- Minimal board-to-RP height (0.041”)

- Dimensional stability during reflow cycles

- Temperature rating up to 500°C

The RP height is the distance from the cable connector's bottom to the board. Minimizing this height is challenging, but SV Microwave has successfully addressed this issue.

Using PTFE, the common dielectric for PCB connectors, often results in growth throughout the solder reflow cycle as the PTFE material cannot withstand the high temperatures found in a solder oven. As shown in the video above, this can cause connectors to “pop” off the boards, affecting signal integrity and requiring expensive rework and product replacements.

Evaluating Dielectrics

When comparing materials used in PCB glass connectors to regular PTFE PCB connectors, it’s easy to see why we at SV Microwave use the Kovar and Corning 7070 Glass Combo. The coefficient of thermal expansions (CTEs) of Kovar and Corning 7070 Glass are closely matched, unlike the more varied CTE of PTFE. Similar CTEs mean minimal damage during heating as both materials expand and contract at comparable rates. PTFE expands more than the Beryllium Copper body due to their varying CTEs, causing more damage. Additionally, Corning 7070 Glass has a melting temperature of approximately 1068°C, far higher than PTFE’s range of 315-399°C.

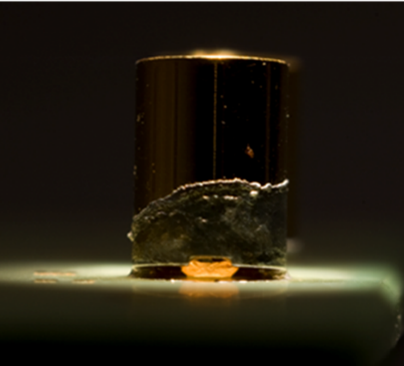

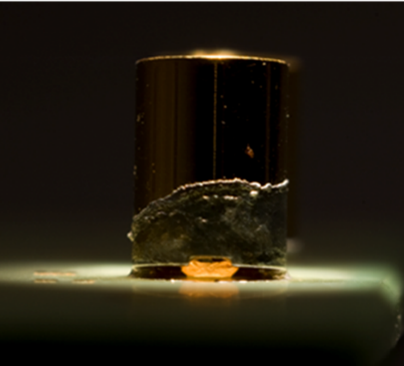

PCB Connector with PTFE tilting and lifting off board during solder reflow

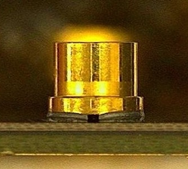

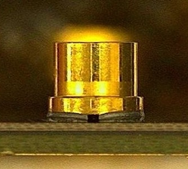

Reflow Stable PCB Connector during reflow. The connector stays firmly on the board

The Need for Kovar/Glass

The solder reflow oven temperature profile for Sn96 solder, one of the higher-temperature solder types, reaches around 250°C, nearing the melt temperature of PTFE. This makes PTFE prone to warping and popping off the board, emphasizing the necessity of Kovar and Glass sealing.

Design Improvements Over PTFE

SV Microwave’s glass-sealed connectors offer several design enhancements:

- Radial Captivation: The glass fused on the pin prevents rotation, protecting the solder joint's integrity.

- Tight Concentricity: High-class fixture vendors ensure tight tolerances, which is crucial for PCB connectors with inserted cable connectors.

- Center Contact Retention: The glass holds the pin much more strongly than a contact would than a PTFE dielectric, which features a barb. This barb affixes the center contact in place but still allows rotation. Using Kovar/Glass materials as the dielectric prevents center contact rotation.

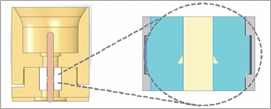

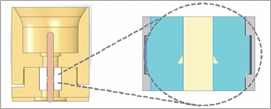

PTFE With Barb

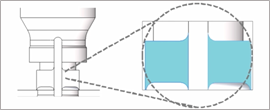

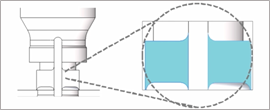

Kovar/Glass

Target Applications

Our glass-sealed connectors are ideal for:

- Phased array systems

- Modular systems

- Communication systems

- Missile guidance systems

- Hi-Rel tests and measurements

These applications often involve large PCBs, where the cost savings from reduced replacements outweigh the higher initial cost of glass-sealed connectors.

Explore our reflow stable products.

SV Microwave’s connectors stand out for their high precision and consistency. We collaborate with top-class fixture vendors and offer custom configurations to meet customer needs. Our commitment is to deliver the best possible product, ensuring reliability and performance.

For any questions or assistance in selecting the right RF connector for your PCB board, SV Microwave’s sales team is here to help! Submit your inquiries.

Join us in embracing cutting-edge technology with SV Microwave’s Reflow Stable RF PCB Connectors!

recent releases

Prevent Mechanical Warping of a PCB Connector during the Solder Reflow Cycle

Discover SV Microwave’s Reflow Stable RF PCB Connectors and their crucial role in preventing mechanical warping during the solder reflow cycle. Read on to learn more about these connectors' manufacturing processes, components, and applications.

Why Choose Reflow Stable Connectors?

The primary advantage of glass-sealed insulated connectors over traditional PTFE insulated connectors is their ability to maintain mechanical integrity and durability during the solder reflow cycle. During this process, PTFE connectors often suffer damage and distortion, while glass-sealed connectors offer superior stability. For engineering companies working on large PCB designs, frequently replacing damaged connectors can be a hassle. Glass-sealed connectors are designed to maintain integrity throughout the reflow cycle, offering multiple benefits:

- Capability of multiple solder reflow cycles

- Minimal board-to-RP height (0.041”)

- Dimensional stability during reflow cycles

- Temperature rating up to 500°C

The RP height is the distance from the cable connector's bottom to the board. Minimizing this height is challenging, but SV Microwave has successfully addressed this issue.

Using PTFE, the common dielectric for PCB connectors, often results in growth throughout the solder reflow cycle as the PTFE material cannot withstand the high temperatures found in a solder oven. As shown in the video above, this can cause connectors to “pop” off the boards, affecting signal integrity and requiring expensive rework and product replacements.

Evaluating Dielectrics

When comparing materials used in PCB glass connectors to regular PTFE PCB connectors, it’s easy to see why we at SV Microwave use the Kovar and Corning 7070 Glass Combo. The coefficient of thermal expansions (CTEs) of Kovar and Corning 7070 Glass are closely matched, unlike the more varied CTE of PTFE. Similar CTEs mean minimal damage during heating as both materials expand and contract at comparable rates. PTFE expands more than the Beryllium Copper body due to their varying CTEs, causing more damage. Additionally, Corning 7070 Glass has a melting temperature of approximately 1068°C, far higher than PTFE’s range of 315-399°C.

PCB Connector with PTFE tilting and lifting off board during solder reflow

Reflow Stable PCB Connector during reflow. The connector stays firmly on the board

The Need for Kovar/Glass

The solder reflow oven temperature profile for Sn96 solder, one of the higher-temperature solder types, reaches around 250°C, nearing the melt temperature of PTFE. This makes PTFE prone to warping and popping off the board, emphasizing the necessity of Kovar and Glass sealing.

Design Improvements Over PTFE

SV Microwave’s glass-sealed connectors offer several design enhancements:

- Radial Captivation: The glass fused on the pin prevents rotation, protecting the solder joint's integrity.

- Tight Concentricity: High-class fixture vendors ensure tight tolerances, which is crucial for PCB connectors with inserted cable connectors.

- Center Contact Retention: The glass holds the pin much more strongly than a contact would than a PTFE dielectric, which features a barb. This barb affixes the center contact in place but still allows rotation. Using Kovar/Glass materials as the dielectric prevents center contact rotation.

PTFE With Barb

Kovar/Glass

Target Applications

Our glass-sealed connectors are ideal for:

- Phased array systems

- Modular systems

- Communication systems

- Missile guidance systems

- Hi-Rel tests and measurements

These applications often involve large PCBs, where the cost savings from reduced replacements outweigh the higher initial cost of glass-sealed connectors.

Explore our reflow stable products.

SV Microwave’s connectors stand out for their high precision and consistency. We collaborate with top-class fixture vendors and offer custom configurations to meet customer needs. Our commitment is to deliver the best possible product, ensuring reliability and performance.

For any questions or assistance in selecting the right RF connector for your PCB board, SV Microwave’s sales team is here to help! Submit your inquiries.

Join us in embracing cutting-edge technology with SV Microwave’s Reflow Stable RF PCB Connectors!