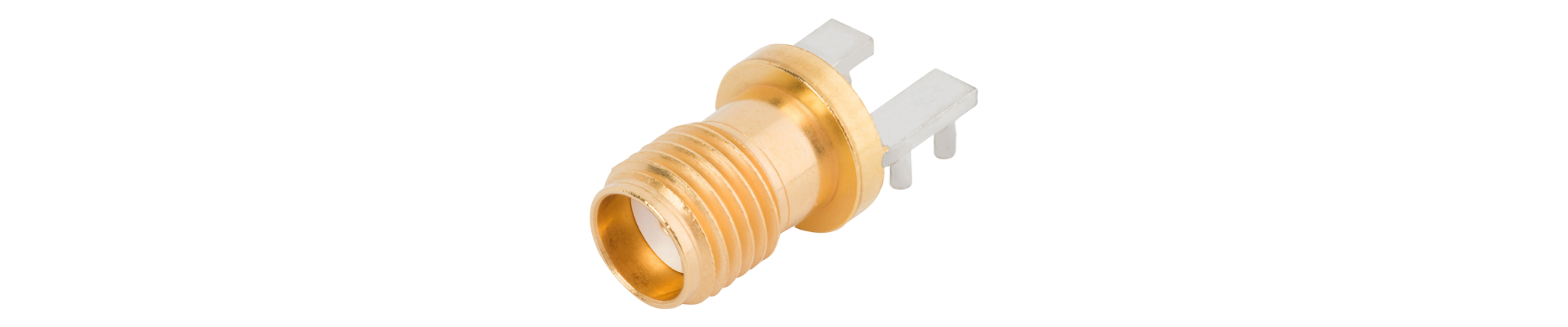

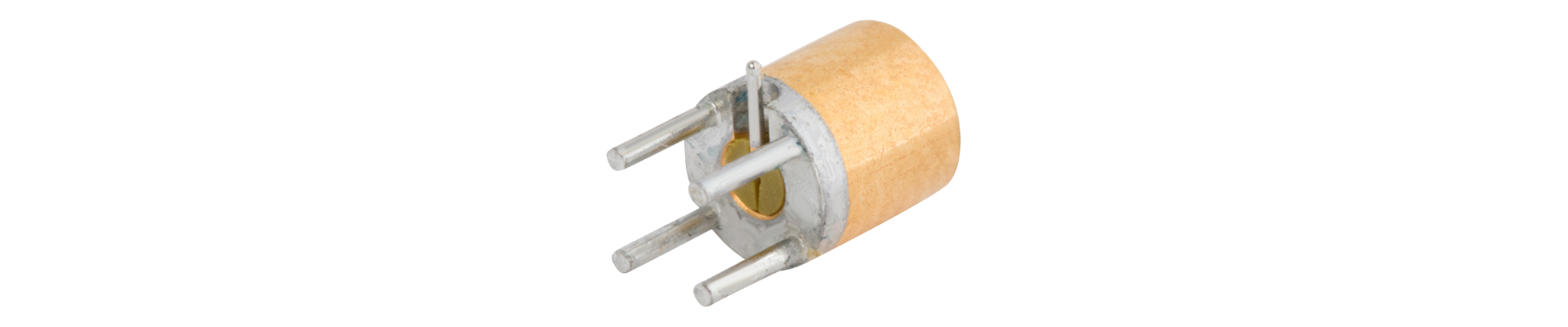

Pre-Tinned (De-Golded) Capabilities

SV Microwave's De-Golding Method

SV Microwave has developed a unique and proprietary method for removing gold in the solder area of our RF connectors. We plan for gold removal in the design stage, modifying the connector body so it can be fixtured effectively and gold can be thoroughly removed from the solderable area - including nearby areas which may be prone to capillary effect wicking.

Why is Gold Removal Important?

Gold over nickel plating is commonly used on Brass, BeCu and Stainless Steel bodies used in RF PCB Connectors. Its corrosion resistance and electrical connectivity make it an excellent choice for signal transmission and high reliability.

However, when these connectors are soldered to PCBs (either by hand or through a reflow process), undesirable remnants of the gold plating can be found in the solder joint. Excess gold in a solder joint can create a gold-tin compound known as AuSn3. These gold striations in the solder joint are brittle - susceptible to breakage under mechanical stress (shock and vibration). For this reason, designers of high vibration and extreme movement RF PCBs often require there to be a minimal amount of Gold in a solder joint, as defined in J-STD-001.

Features and Benefits

- Gold in soldered area removed per J-STD-001

- Improves reliability of the solder joint

- Connectors optimized for pre-tinning at the design stage

- Parts delivered in T&R packaging and ready to install

- Cost savings compared to outsourcing or de-golding in house

- Pre-tinning options available in both SN63 and SN96

- Robust technical support for design, assembly and trouble-shooting

- Footprint design optimization through simulation available

image2.png)

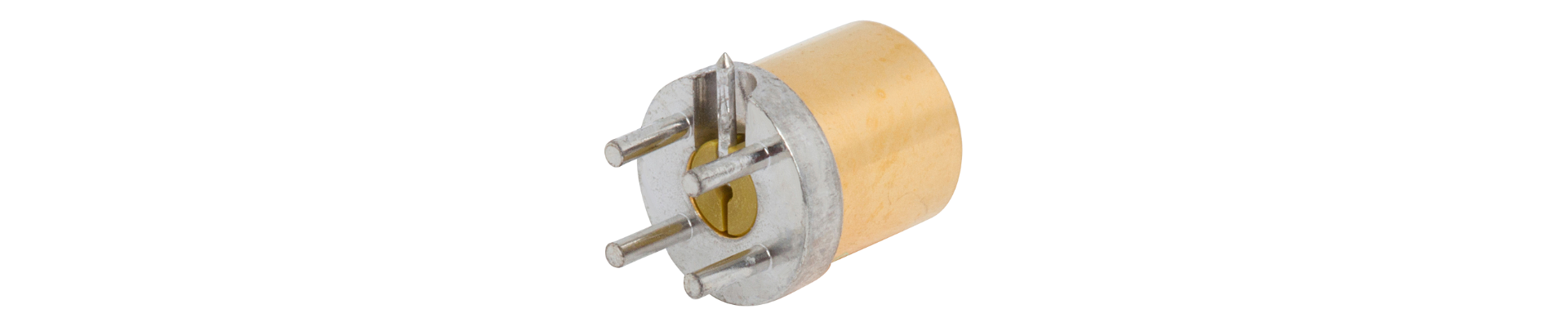

Applications

- Military and Aerospace Radar Transmit/Receive Units

- Space and High Reliability Communications and GPS

- Harsh Environment Applications (High Vibration, Extreme Temp.)

- Embedded Computing

- Any time de-golding is a concern or requirement

image3.png)

.png)