How well do Right Angle RF Connectors Work?

Right angle connectors are a common solution for applications with tight routing. SV Microwave provides right angle cable connectors, adapters, and PCB connectors across threaded and push-on series. Over time, the presentation of our right angle solutions has evolved to take on three separate forms.

We will examine the differences, and electrical performance of each: Solder Fork, Swept Body and Contact, and Mitered Body and Swept Contact. Though at first glance these can look very similar, there are some differences in the construction of each that we will get into:

Solder Fork

These connectors were the first evolution in the production of right angle connectors. They typically feature a cap towards the rear of the connector that provides access to solder the two center contacts together. While visually similar to the Mitered Body/Swept Contact design, one important difference is in the contact. The contact within the Solder Fork is in two pieces, where as a swept contact is one piece that is bent. SV’s SF2994-6001, SMA Female to Male Adapter, R/A, is a representative example of a Solder Fork Right Angle Connector. Capable of DC -12.4 GHz.

Swept Body and Contact

Unlike the Solder Fork, the external housing for these is one solid piece. A straight housing is machined and then bent at a 90°angle. It’s difficult to machine the housing of these connectors to match the bend of the contact, and thus these connectors may have inconsistent RF performance. but at its best, this type of right angle connector can provide performance up to 18 GHz.

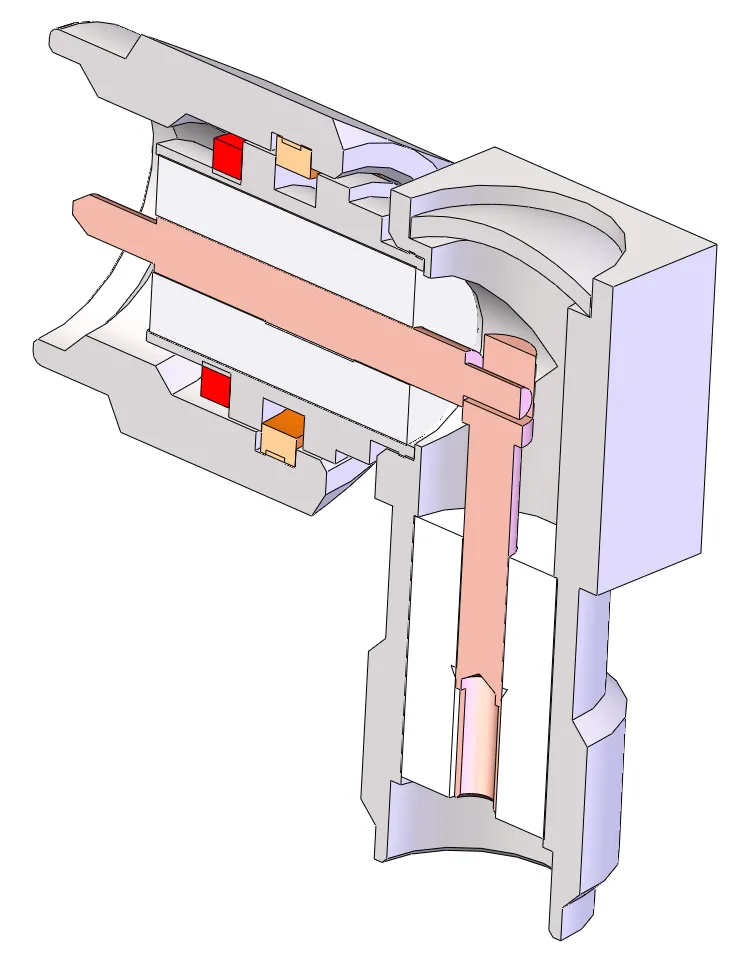

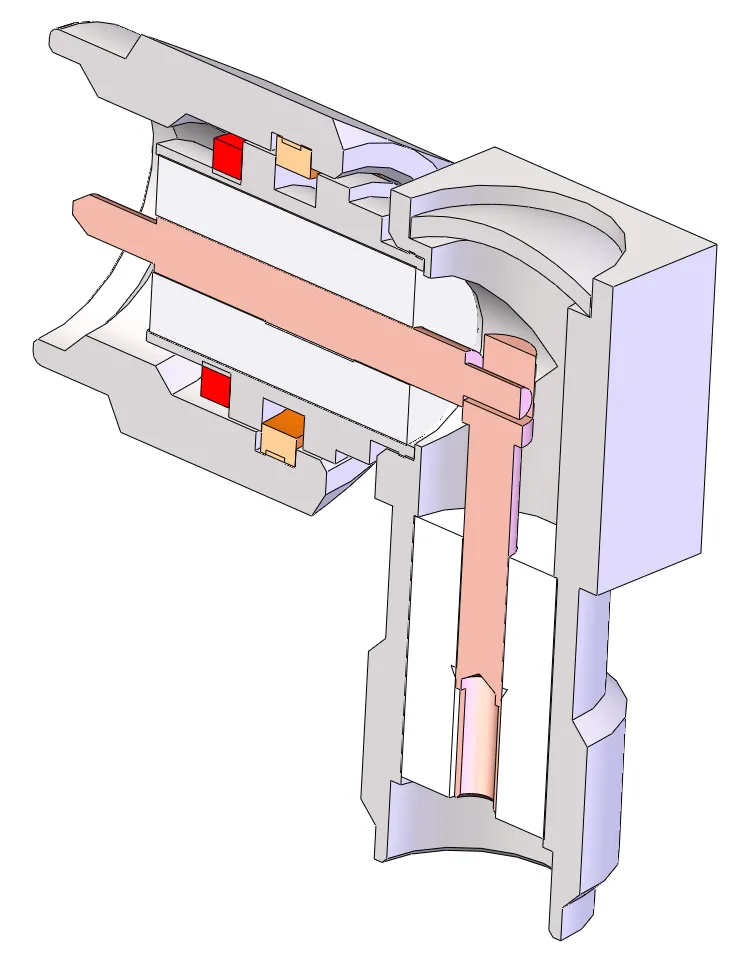

Mitered Body/Swept-Contact

The Mitered Body/Swept-Contact provides the best of both the Solder Fork and the Swept Body/Contact constructions. The body of a mitered connector is two separate machined parts that are fused around a swept contact. This connector has improved RF performance over both its predecessors consistently performing up to 18 GHz with a lower VSWR and Insertion Loss.

Electrical Performance Data

We examined right angle SMA adapters of both Mitered Body and Swept Body designs and established a clear advantage in the mitered body design for both VSWR and Insertion Loss.

About SV Microwave

SV Microwave is a world leader in the RF/Microwave industry with over 50 years of proven performance. We design and manufacture RF/Microwave coaxial connectors, cable assemblies and passive components designed for military, IoT, 5G, satellite, high speed, aerospace, commercial and telecommunications applications. Our product lines include commercial off the shelf (COTS) items and custom, highly reliable, highly repeatable products. When it comes to the design and manufacture of custom products, SV Microwave has set the standard in RF and microwave connectors, components, adapters and cable assemblies. SV Microwave is committed to helping customers meet their RF/Microwave performance goals with our highly talented engineering staff and extremely responsive sales team.

recent releases

How well do Right Angle RF Connectors Work?

Right angle connectors are a common solution for applications with tight routing. SV Microwave provides right angle cable connectors, adapters, and PCB connectors across threaded and push-on series. Over time, the presentation of our right angle solutions has evolved to take on three separate forms.

We will examine the differences, and electrical performance of each: Solder Fork, Swept Body and Contact, and Mitered Body and Swept Contact. Though at first glance these can look very similar, there are some differences in the construction of each that we will get into:

Solder Fork

These connectors were the first evolution in the production of right angle connectors. They typically feature a cap towards the rear of the connector that provides access to solder the two center contacts together. While visually similar to the Mitered Body/Swept Contact design, one important difference is in the contact. The contact within the Solder Fork is in two pieces, where as a swept contact is one piece that is bent. SV’s SF2994-6001, SMA Female to Male Adapter, R/A, is a representative example of a Solder Fork Right Angle Connector. Capable of DC -12.4 GHz.

Swept Body and Contact

Unlike the Solder Fork, the external housing for these is one solid piece. A straight housing is machined and then bent at a 90°angle. It’s difficult to machine the housing of these connectors to match the bend of the contact, and thus these connectors may have inconsistent RF performance. but at its best, this type of right angle connector can provide performance up to 18 GHz.

Mitered Body/Swept-Contact

The Mitered Body/Swept-Contact provides the best of both the Solder Fork and the Swept Body/Contact constructions. The body of a mitered connector is two separate machined parts that are fused around a swept contact. This connector has improved RF performance over both its predecessors consistently performing up to 18 GHz with a lower VSWR and Insertion Loss.

Electrical Performance Data

We examined right angle SMA adapters of both Mitered Body and Swept Body designs and established a clear advantage in the mitered body design for both VSWR and Insertion Loss.

About SV Microwave

SV Microwave is a world leader in the RF/Microwave industry with over 50 years of proven performance. We design and manufacture RF/Microwave coaxial connectors, cable assemblies and passive components designed for military, IoT, 5G, satellite, high speed, aerospace, commercial and telecommunications applications. Our product lines include commercial off the shelf (COTS) items and custom, highly reliable, highly repeatable products. When it comes to the design and manufacture of custom products, SV Microwave has set the standard in RF and microwave connectors, components, adapters and cable assemblies. SV Microwave is committed to helping customers meet their RF/Microwave performance goals with our highly talented engineering staff and extremely responsive sales team.