Thermal Shock Testing for RF Connectors

What is Thermal Shock Testing?

Thermal shock testing is a meticulous evaluation process that assesses the reliability and durability of materials or components. It involves subjecting them to large and sudden temperature changes, thereby analyzing their ability to withstand stressful environments. This testing aids in determining the RF connector’s capability of handling its intended applications, storage, and transportation.

Thermal Shock Testing for Connectors

Thermal shock testing is crucial in the connector hardiness verification. The RF connectors undergo thermal shock, and their resilience to this stress and any resultant changes are meticulously observed, emphasizing the vital role of our work in ensuring their reliability and durability.

Thermal Shock Testing at SV Microwave

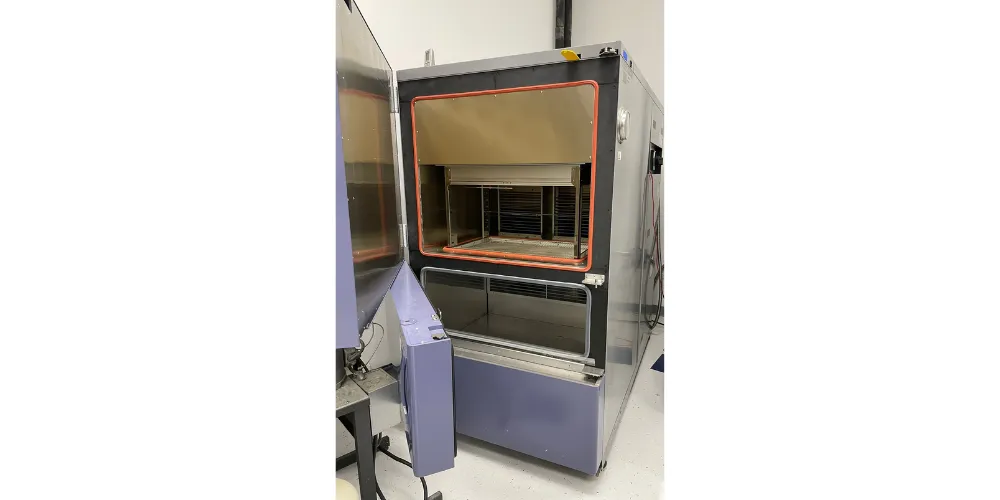

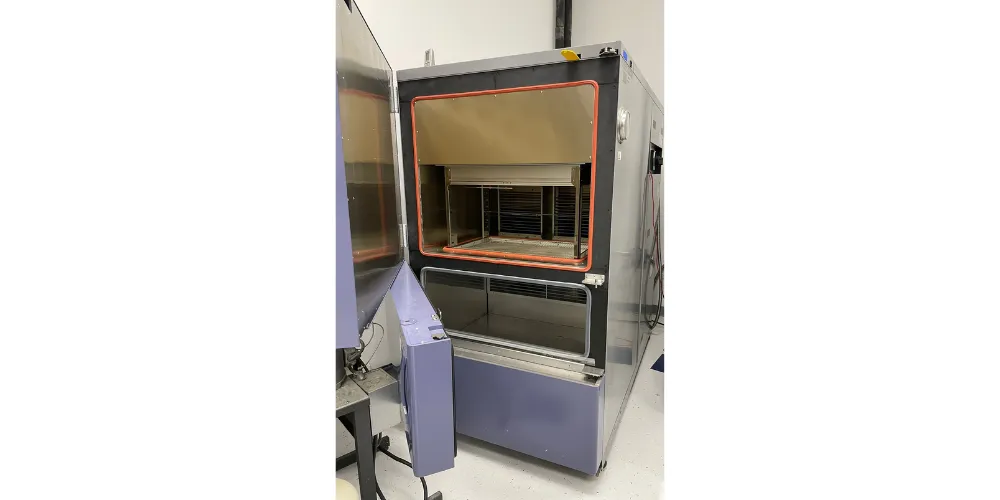

SV Microwave uses a specialized environmental chamber oven/fridge for thermal shock testing. An internal elevator moves the parts between independently hot and cold chambers without exposing them to the outside atmosphere.The large and rapid temperature gradient can introduce stresses in the connector due to expansion and contraction, which can cause failures. Different materials expand and contract at different rates, which can drive excessive interference or undesirable gaps to form. Press-fits could become undone or parts that are supposed to slip past each other may no longer do so.

Thermal Shock Testing Chamber

Environmental Conditions

Aside from thermal shock testing, SV is able to provide rigorous environmental testing for a desired product. We can rate our products to the MIL-STD 202 under the following conditions:

- Temperature Rating: -65°C to +165°C

- Corrosion: MIL-STD-202, Method 101, Condition B

- Shock: MIL-STD-202, Method 213, Condition I

- Vibration: MIL-STD-202, Method 204, Condition D

- Thermal Shock: MIL-STD-202, Method 107, Condition B

- Moisture Resistance: MIL-STD-202, Method 106, Less Step 7B

- Barometric Pressure: MIL-STD-202, Method 105, Condition C, 70k Ft.

Evaluation Criteria

- Physical - Inspecting for cracks, distortions, and any other physical damages.

- Electrical – SV ensures no significant changes in relevant electrical requirements, such as VSWR or Insertion Loss.

- Mechanical - Ensuring the mechanical aspects are within permissible limits, like mating force and contact retention.

recent releases

Thermal Shock Testing for RF Connectors

What is Thermal Shock Testing?

Thermal shock testing is a meticulous evaluation process that assesses the reliability and durability of materials or components. It involves subjecting them to large and sudden temperature changes, thereby analyzing their ability to withstand stressful environments. This testing aids in determining the RF connector’s capability of handling its intended applications, storage, and transportation.

Thermal Shock Testing for Connectors

Thermal shock testing is crucial in the connector hardiness verification. The RF connectors undergo thermal shock, and their resilience to this stress and any resultant changes are meticulously observed, emphasizing the vital role of our work in ensuring their reliability and durability.

Thermal Shock Testing at SV Microwave

SV Microwave uses a specialized environmental chamber oven/fridge for thermal shock testing. An internal elevator moves the parts between independently hot and cold chambers without exposing them to the outside atmosphere.The large and rapid temperature gradient can introduce stresses in the connector due to expansion and contraction, which can cause failures. Different materials expand and contract at different rates, which can drive excessive interference or undesirable gaps to form. Press-fits could become undone or parts that are supposed to slip past each other may no longer do so.

Thermal Shock Testing Chamber

Environmental Conditions

Aside from thermal shock testing, SV is able to provide rigorous environmental testing for a desired product. We can rate our products to the MIL-STD 202 under the following conditions:

- Temperature Rating: -65°C to +165°C

- Corrosion: MIL-STD-202, Method 101, Condition B

- Shock: MIL-STD-202, Method 213, Condition I

- Vibration: MIL-STD-202, Method 204, Condition D

- Thermal Shock: MIL-STD-202, Method 107, Condition B

- Moisture Resistance: MIL-STD-202, Method 106, Less Step 7B

- Barometric Pressure: MIL-STD-202, Method 105, Condition C, 70k Ft.

Evaluation Criteria

- Physical - Inspecting for cracks, distortions, and any other physical damages.

- Electrical – SV ensures no significant changes in relevant electrical requirements, such as VSWR or Insertion Loss.

- Mechanical - Ensuring the mechanical aspects are within permissible limits, like mating force and contact retention.